- Send Us Email

- response@ecoindustrialburners.com

- Saving Upto 60% On Fuel Cost

Ecoflam Oil Burner

Description

lternative heating without gas, namely Feed screw 3 M is the most promising in development and application for the organization of an economical heating system in your home.

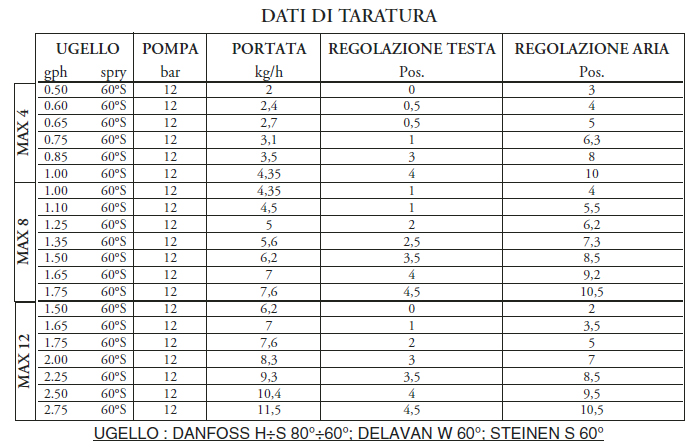

NOZZLE : DANFOSS H÷S 80°÷60°; DELAVAN W 60°; STEINEN S 60°

|

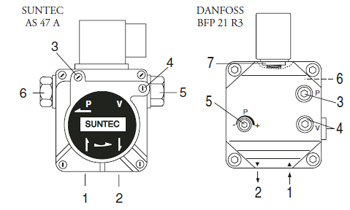

PRIMING AND ADJUSTMENT OF OIL PUMP 1 - INLET 2 - RETURN 3 - BLEED AND PRESSURE GAUGE PORT 4 - VACUUM GAUGE PORT 5 - PRESSURE ADJUSTMENT 6 - TO NOZZLE 7 - CARTRIDGE FILTER |

| VERIFY: * That piping system is perfectly sealed. * That the use of hoses is avoided whenever is possible (use copper pipes preferably). * That depression is not greater than 0,45 bar, to avoid pump’s cavitation. |

|

|

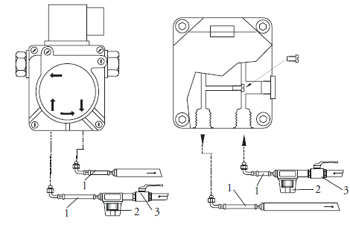

1 - HOSE 2 - OIL FILTER 3 - OIL COCK That check valve is suitably designed for the duty. The pump pressure is set at a value of 12 bar during the testing of burners. Before starting the burner, bleed the air in the pump through the gauge port. Fill the piping with light-oil to facilitate the pump priming. |

| Start the burner and check the pump feeding pressure. In case the pump priming does not take place during the first prepurging, with a consequent, subsequent lock-out of the burner, rearm the burner’s lock-out to restart, by pushing the button on the control box. If, after a successful pump priming, the burner locks-out after the prepurging, due to a fuel pressure drop in the pump, rearm the burner’s lock-out to restart the burner. Do never allow the pump working without oil for more than three minutes. |

|

| Note : before starting the burner, check that the return pipe is open. An eventual obstruction could damage the pump sealing device. | |

| Technical Data | |||

| Model | Max 20 | Max 30 | |

| Thermal power max. | kcal/h | 204.000 | 275.400 |

| kW | 237 | 319 | |

| Thermal power man. | kcal/h | 74.460 | 94.860 |

| kW | 86,4 | 110 | |

| Max. Flow Rate Light Oil | kg/h | 20 | 27 |

| Min. Flow Rate Light Oil | kg/h | 7,3 | 9,3 |

| Feeding Power | 50 Z V | 220 | 220 |

| Motor | W | 200 | 200 |

| Rpm | N° |

2.800 | 2.800 |

| Ignition Transformer | kV/mA | 2×7,5/40 | 2×7,5/40 |

| Control Box | LANDIS | LOA 24 | LOA 24 |

| Fuel: Light Oil | kcal/kg | 10.200 max. visc 1,5°E a 20°C | |

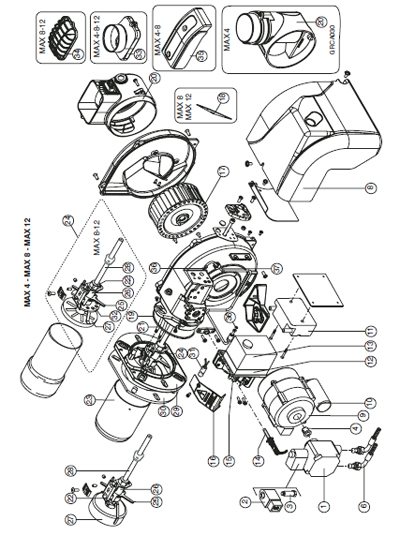

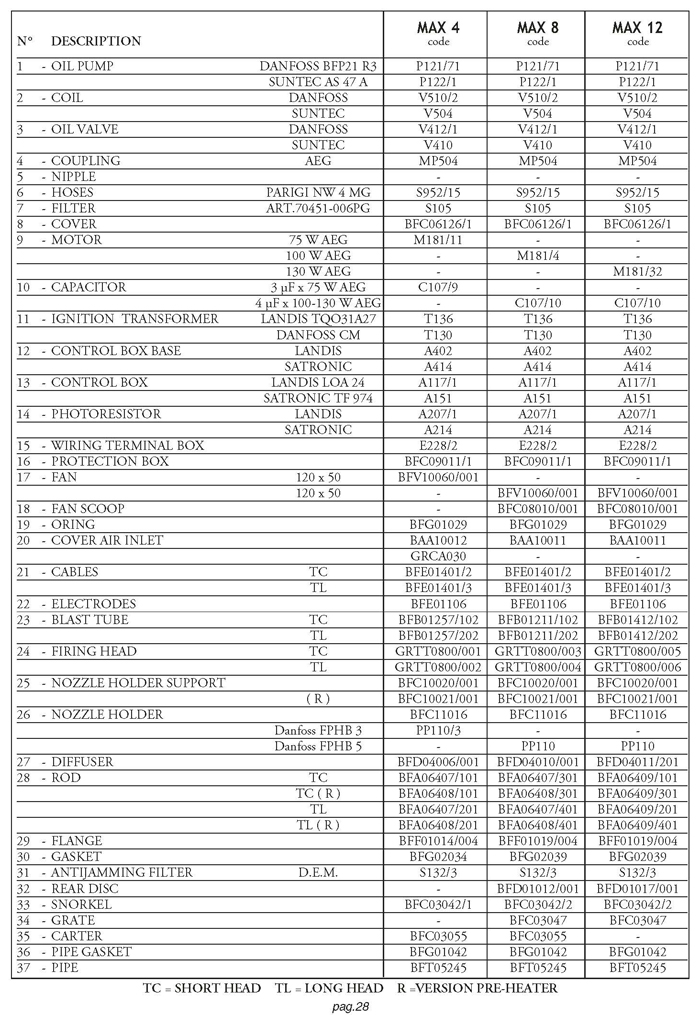

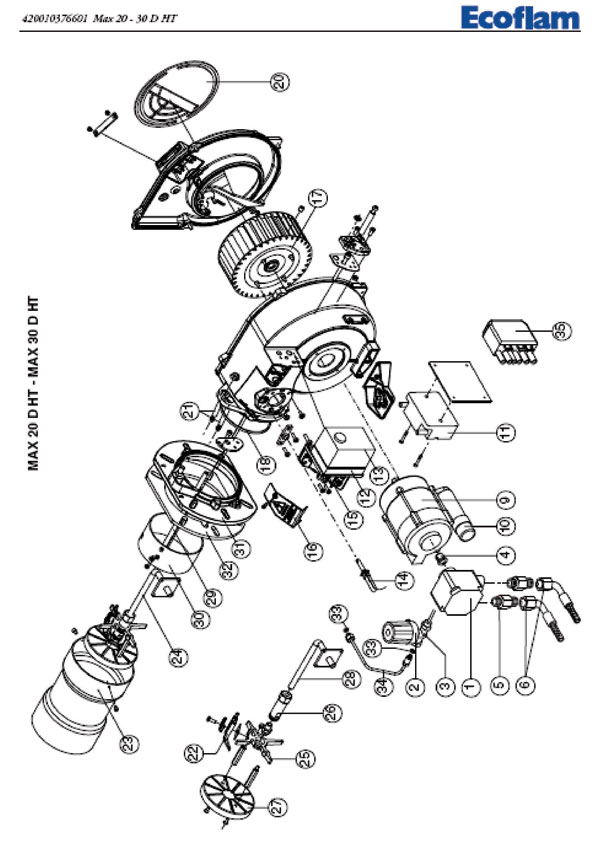

| No. | DESCRIPTION | MAX 20 D HT | MAX 30 D HT | |

| Code | Code | |||

| 1 | Oil Pump | SUNTEC D 57 A | 65322959 | 65322959 |

| 2 | Coil | BRAHMA E 7/L | 65323762 | 65323762 |

| 3 | Oil Valve | BRAHMA E 7/L | 65323737 | 65323737 |

| 4 | Coupling | 65322920 | 65322920 | |

| 5 | Nipple | TN 6 X 700 | 65321179 | 65321179 |

| 6 | Hoses | TN 6 X 700 | 65323189 | 65323189 |

| 7 | Filter | ART 70451-006AV | 65325046 | 65325046 |

| 8 | Cover | - | 65320594 | |

| 9 | Motor | 200 W | 65322876 | 65322876 |

| 10 | Capacitor | 6 µF AEG | 65321850 | 65321850 |

| 6,3 µF SIMEL | 65325000 | 65325000 | ||

| 11 | Ignition Transformer | COFT E820 CM | 65323243 | 65323243 |

| 12 | Control Box Base | LANDIS | 65320092 | 65320092 |

| 13 | Control Box | LANDIS LOA 24 | 65320028 | 65320028 |

| 14 | Photoresistor | LANDIS | 65320076 | 65320076 |

| 15 | Wiring Terminal Box | 65324058 | 65324058 | |

| 16 | Protection Box | 65320663 | 65320663 | |

| 17 | Fan | 160×62 | 65323820 | 65323820 |

| 18 | Oring | 65321061 | 65321061 | |

| 19 | Air Damper | - | - | |

| 20 | Cover Air Inlet | 65321216 | 65321216 | |

| 21 | Cables | TC | 65320935 | 65320935 |

| TL | 65320937 | 65320937 | ||

| TL (350) | 65320939 | 65320939 | ||

| 22 | Electrodes | 65320924 | 65320924 | |

| 23 | Blast Tube | TC | 65320396 | 65320393 |

| TL | 65320392 | 65320392 | ||

| TL (AISI) | 65320397 | - | ||

| TL (350) | - | 65325103 | ||

| 24 | Firing Head | - | - | |

| 25 | Nozzles Holder Support | 65320690 | 65320690 | |

| 26 | Nozzle Holder | 65320707 | 65320707 | |

| 27 | Diffuser | 65320789 | 65320790 | |

| 28 | Rod | TC | 65320191 | 65320191 |

| TL | 65320192 | 65320192 | ||

| TL (350) | - | 65325104 | ||

| 29 | Waistband Rod | TC | 65320195 | 65320195 |

| TL | 65320196 | 65320196 | ||

| TL (350) | - | 65325105 | ||

| 30 | Waistband | 65320224 | 65320224 | |

| 31 | Flange | 65320971 | 65320971 | |

| 32 | Gasket | 65321106 | 65321106 | |

| 33 | Pipe Gasket | 65321065 | 65321065 | |

| 34 | Pipe | 65321502 | 65321502 | |

| 35 | socket wieland | 7 Pin | - | 65322070 |

MAX 30 D HT